Difference between split system and multi-split system:

The difference between separate split system and multi-split system with several indoor units is that all the indoor units are connected to the main external unit, but the principle of their operation is similar to a simple split-system.

This unique feature of a multi-split might be the right solution for maintaining the microclimate in several offices, shops, large living spaces. The main external unit can be connected to several different indoor types: floor, ceiling, cassette, etc. with just only a few of this outdoor units you do not worsen the aesthetic appearance of the building.

Multi-split system installation considerations

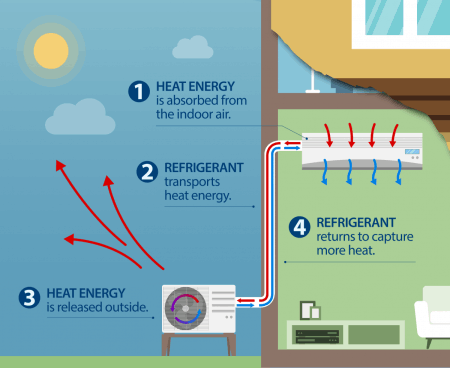

Before selecting the installation location of air conditioner, several main factors need to be considered. First of all, the direction of air flow from the indoor units should not fall on the place of rest or work area. Secondly, there should not be any obstacles on the way of the airflow that might prevent it from covering the space of the premises as much as possible. The outdoor unit must also be located in an open space, otherwise the heat from the house will not be effectively discharged outside and the productivity of the entire system will drop sharply. It is highly advisable to install the air conditioner units in easily accessible places, for further maintenance during operation.

The main problem when installing a multi-split system is the laying of long refrigerant lines for connecting the external unit to the internal ones. While installing a separate split system, workers try to locate both units opposite to each other, where the length of the line is minimal. Installing a multi-split system creates more difficulties, since some of indoor units can be located far from the outside. The first models of multi-split systems had one common control system that did not allow you to set the air conditioning individually for each room. However, now the market has a wide selection of multi-split systems, in which the functional characteristics of indoor units operate separately from each other.

The selection of indoor units has one restriction: their total power should not exceed the capacity of the outdoor unit. In practice, however, it is very common to see a multi-split system with a total capacity of indoor units greater than the outdoor capacity by at least 20%. However, it is wrong to expect better performance when all indoor units are turned on at the same time, since the total capacity of the whole system is limited by the capacity of the outdoor unit. Simply put, the outdoor unit will distribute all its power to all operating indoor units in such a way that some of the rooms may not have a very comfortable temperature level. However, the calculation of the total power is not simple, since it takes into account not only the nominal power of the units, but also the cooling capacity, heating, dehumidification, humidification, venting, etc.

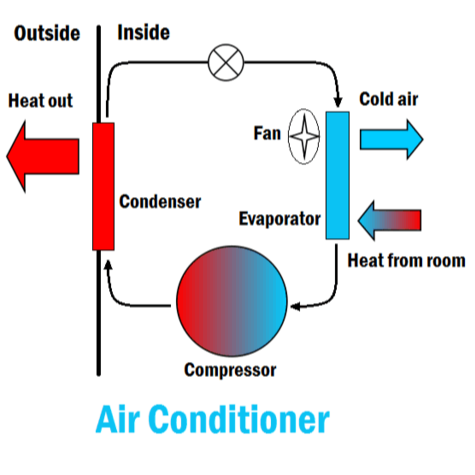

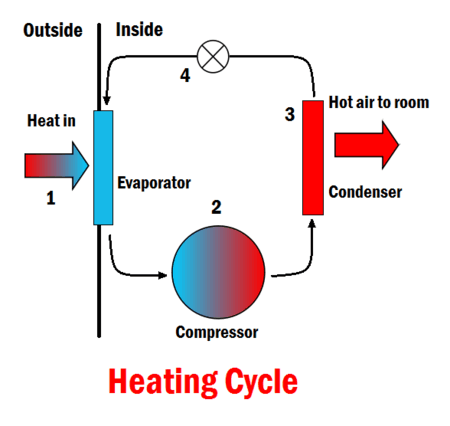

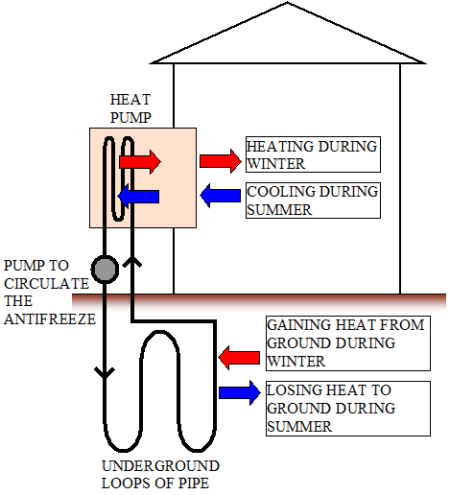

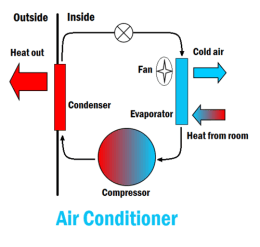

Split-system air conditioners come in two forms: mini-split and central systems. In both types, the inside-environment (evaporative) heat exchanger is separated by some distance from the outside-environment (condensing unit) heat exchanger.